Release time:2021-12-06Click:1028

The surface of high manganese aluminum bronze was treated by laser remelting, and the microstructure was observed, electrochemical testing and ultrasonic vibration cavitation erosion were carried out, the effects of laser remelting on microstructure, corrosion and cavitation erosion of as-cast high manganese aluminum bronze were investigated. The results show that the microstructure is refined and the grain distribution is uniform after remelting, and the hardness is increased by about 45% compared with as-cast alloy. The results of electrochemical experiments show that the electrode reaction process of remelted alloy is similar to that of as-cast alloy, but the corrosion potential of as-cast alloy is lower and the corrosion tendency is higher. The results show that the weight loss rate of remelted alloy is only 3/5 of that of as-cast alloy after 5 H cavitation erosion in 3.5% NACL solution. The results of cavitation erosion morphology show that the surface damage of the remelted alloy is less than that of the cast alloy, and the surface damage is less than that of the Surface roughness alloy. The weight loss of as-cast and laser remelted alloys due to pure cavitation erosion is 71.1% and 50.8% , respectively.

Key words: High Manganese Aluminum Bronze; laser remelting; corrosion; cavitation; interaction the ocean is rich in material resources, and with the development of ocean economy and exploitation of ocean resources, more and more large-scale equipment needs to be built and applied in the marine environment. Propeller is an important marine power plant. With the development of high-speed and large-scale ships, the performance of propeller materials is required to be higher and higher. In addition to the static electrochemical corrosion, the surface of the propeller is exposed to cavitation corrosion due to the high relative motion of the propeller and seawater, the interaction of cavitation erosion and corrosion will make the surface damage of propeller material more and more serious, and reduce the efficiency of propeller greatly.

High Manganese Aluminum Bronze (Mab) is widely used in the manufacture of large marine propellers because of its high strength, corrosion resistance to seawater and atmosphere, and excellent casting properties. MAB was developed by adding MN, FE, NI and other alloying elements into Cu-Al alloy. The microstructure of CAST MAB alloy at room temperature is complex, including α phase, β phase and κ phase. There are many defects in the MAB casting, such as component segregation, coarse grain, internal porosity and stress concentration, and contact with a large number of marine organisms in the marine environment, thus pitting corrosion, cavitation corrosion, erosion corrosion, corrosion fatigue and other problems, which will lead to a sharp decline in the service life of the propeller. The effective surface modification of MAB casting is the key to improve its corrosion and cavitation corrosion properties. The technology of laser surface modification is to improve the structure and properties of metal surface by high energy laser beam. Compared with the traditional technology, the laser surface modification technology can improve the surface properties of materials while maintaining the original structure and properties of the Matrix metal. For example, laser surface remelting (LSM) can reduce or eliminate casting defects, improve material segregation and refine grain without adding any metal elements. This is because the energy-focused laser beam can rapidly melt the surface of the material to form a molten pool, and at the same time, can rapidly cool to obtain uniform and dense non-equilibrium microstructure. In this paper, the surface of as-cast Mab was treated by Lsm, and the microstructure and morphology were observed, and the hardness, electrochemical and cavitation erosion weight were measured, the effect of Lsm on the corrosion and cavitation of as-cast Mab in 3.5% NACL solution was investigated.

High Manganese Aluminum Bronze (Mab) is widely used in the manufacture of large marine propellers because of its high strength, corrosion resistance to seawater and atmosphere, and excellent casting properties. MAB was developed by adding MN, FE, NI and other alloying elements into Cu-Al alloy. The microstructure of CAST MAB alloy at room temperature is complex, including α phase, β phase and κ phase. There are many defects in the MAB casting, such as component segregation, coarse grain, internal porosity and stress concentration, and contact with a large number of marine organisms in the marine environment, thus pitting corrosion, cavitation corrosion, erosion corrosion, corrosion fatigue and other problems, which will lead to a sharp decline in the service life of the propeller. The effective surface modification of MAB casting is the key to improve its corrosion and cavitation corrosion properties. The technology of laser surface modification is to improve the structure and properties of metal surface by high energy laser beam. Compared with the traditional technology, the laser surface modification technology can improve the surface properties of materials while maintaining the original structure and properties of the Matrix metal. For example, laser surface remelting (LSM) can reduce or eliminate casting defects, improve material segregation and refine grain without adding any metal elements. This is because the energy-focused laser beam can rapidly melt the surface of the material to form a molten pool, and at the same time, can rapidly cool to obtain uniform and dense non-equilibrium microstructure. In this paper, the surface of as-cast Mab was treated by Lsm, and the microstructure and morphology were observed, and the hardness, electrochemical and cavitation erosion weight were measured, the effect of Lsm on the corrosion and cavitation of as-cast Mab in 3.5% NACL solution was investigated.

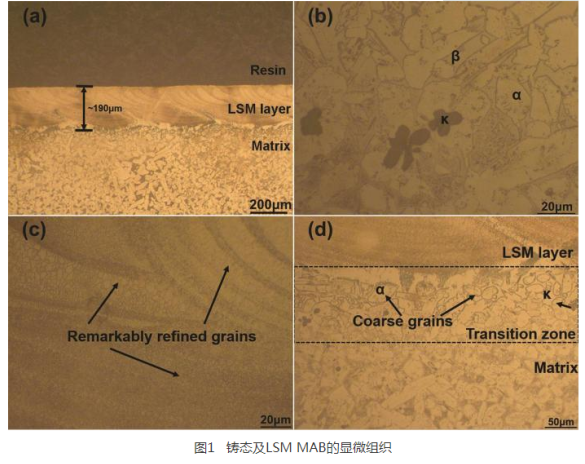

2. Results and discussion 2.1 microstructure and hardness analysis as-cast and microstructure of Lsm Mab as shown in Fig. 1. Fig. 1A is the overall cross-section. After LSM treatment with the laser power of 5kw and the scanning speed of 60mm/min, the remelted layer depth is about 190μm. The region from the LSM MAB surface to the substrate includes the laser remelting region and the transition region. Fig. 1B shows the microstructure of the Matrix, which is composed of α phase, β phase and κ phase. Each phase is relatively large in size. The grains in the remelting zone are homogeneous and fine single-phase β. As shown in Fig. 1C, the component inhomogeneity caused by the casting process disappears. Due to the cooling of the protective gas and the excellent heat conduction of the Copper Alloy Matrix, the cooling rate of the molten pool is very fast, and the α and κ phases in the original cast structure can not be precipitated, thus a single fine β phase structure can be obtained. The transition zone structure shown in Fig. 1D contains coarse α and κ phases. The effect of laser heating on the region is weak, resulting in incomplete melting of the region and some coarse κ phases remaining, because of no cooling effect of protective gas, the cooling rate of some remelted tissues is slow and α phase is precipitated.

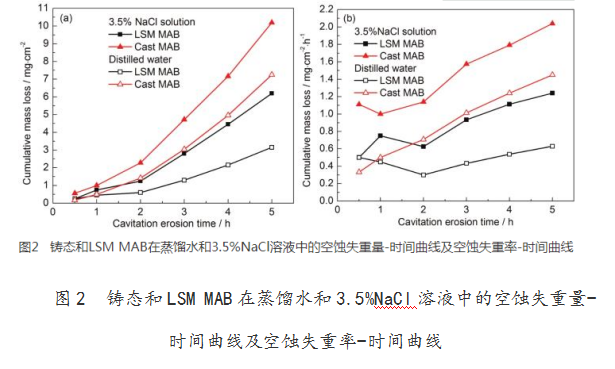

The vickers hardness test of Lsm Mab and as-cast Mab shows that the average microhardness of the Matrix is about 176hv, and the average microhardness of the remelted zone after LSM treatment is 256hv, which is about 45% higher than that of the Matrix. Compared with as-cast Mab, LSM treatment resulted in grain refinement. According to Hall-Petch formula, the grain size decreases and the microhardness increases. 2.2 cavitation weight loss results and analysis of as-cast and LSM MAB in distilled water and 3.5% NACL solution as shown in figure 2. The weight loss rate of LSM MAB is about 0.6300 MG cm-2 h-1 and the incubation period is about 2 hours after cavitation in distilled water for 5 hours, while the weight loss rate of as-cast Mab is about 1.4500 MG cm-2 h-1, about 2.3 times as that of Lsm Mab, and the incubation period is about 1 hour. In 3.5% NACL solution, the incubation period of as-cast Mab was short, about 0.5 h, and the weight loss rate increased rapidly in a short time, while the weight loss rate of Lsm Mab increased slowly, the incubation period was about 1 h. The weight loss rate of as-cast Mab was 2.0389 MG cm-2 h-1 after 5 hours of Cavitation, while that of LSM MAB was only 1.2400 MG cm-2 h-1, which was 3/5 of as-cast sample. It can be seen that LSM treatment can improve the cavitation resistance of as-cast Mab by about 1.64 times, which benefits the improvement of surface hardness and the homogenization of microstructure. In addition, the weight loss rate of as-cast and LSM MAB in 3.5% NACL solution is higher than that in distilled water due to the interaction between corrosion and cavitation.

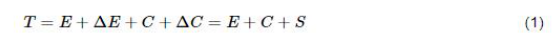

2.3 cavitation-corrosion interaction analysis in corrosive media, there is interaction between cavitation and corrosion, and the damage caused by the interaction is much greater than the sum of the effects alone. The cavitation damage of materials includes pure cavitation damage, pure corrosion damage and corrosion-cavitation interaction damage. The interaction between corrosion and cavitation can be expressed by the following formula [10] :

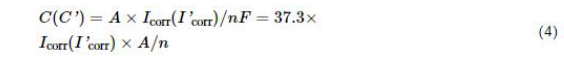

In the formula, t is the cumulative mass loss in 3.5% NACL solution, e is the pure mass loss in distilled water and C is the pure mass loss in static state S is the mass loss due to cavitation and corrosion interactions, including cavitation damage enhanced by corrosion? E and corrosion damage enhanced by cavitation? “C.”. Both can be calculated using the following formula:

In the formula, C’is the corrosion quality loss under cavitation condition. C and C’can be determined from the following formula:

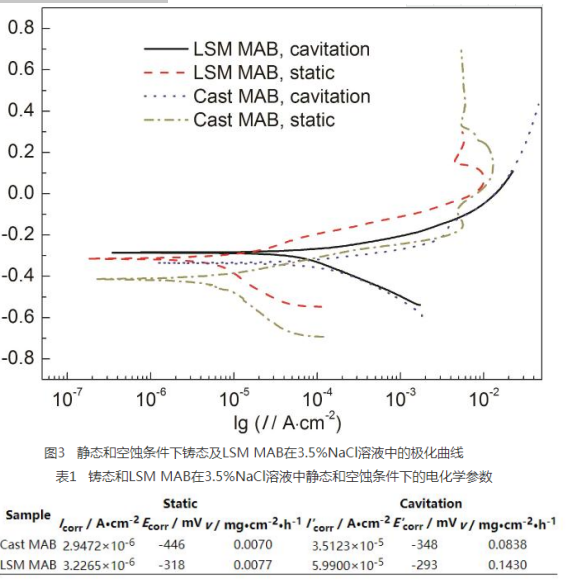

Where a is the atomic weight of the metal, the main consideration here is the Cu Matrix, so a = 64g mol-1; N is the valence of the metal, the number of electrons in the anodic reaction equation, plus 1; F is the Faraday constant, with a value of 96500C MOL-1; ICORR and I’Corr are corrosion current density (a cm-2) under static and cavitation conditions respectively, which can be obtained by electrochemical measurement. Figure 3 shows the polarization curves measured by as-cast and Lsm Mab under static and cavitation conditions in 3.5% NACL solution. The corrosion potential, corrosion current density and corrosion rate of as-cast and LSM MAB under static and cavitation conditions in 3.5% NACL solution are shown in Table 1. Under static conditions, the CATHODIC and anodic processes of the two samples are similar. The CATHODIC reaction is an oxygen reduction process: o 2 + 2 h 2O + 4 e →4 oh-[11,12] . LSM does not change the chemical composition of the material, so the anodic process is not changed, mainly the dissolution of Cu: Cu + 2cl-→ cucl2-+ E-[11,12] .

The static corrosion potentials of as-cast and LSM MAB were-446 and-318 MV, respectively. The corrosion potentials of as-cast and LSM MAB were-348 and-293 MV, respectively. It can be seen that cavitation corrosion will cause the corrosion potential to move forward. CAVITATION damages the corrosion product film on the surface of the material on one hand, and accelerates the mass transfer process on the other hand, the former makes the potential lower, the latter makes the potential higher, if no protective corrosion product film is formed on the surface of the material, the latter then dominates, and the result is a positive potential shift due to Cavitation [13-15] . The corrosion current densities of as-cast and Lsm Mab were 2.9472 × 10-6 and 3.2265 × 10-6 a cm-2, respectively. Compared with the static state, the corrosion current density of the cast and Lsm Mab is 3.5123 × 10-5 and 5.9900 × 10-5 a cm-2 respectively. It can be seen that the corrosion current of as-cast and Lsm Mab is similar under static and cavitation conditions, which is due to the oxygen reduction reaction in 3.5% NACL solution, and the corrosion rate of the material is controlled by oxygen diffusion. The diffusion of oxygen is accelerated under cavitation condition, so the corrosion current density is higher than that under static condition.

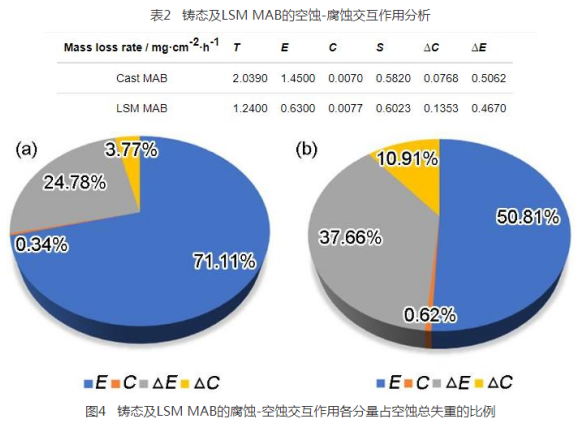

Combined with the formula (1 ~ 4) , the cavitation weight loss caused by different components can be calculated, as shown in Table 2. Figure 4 shows the ratio of weight loss to total weight loss of LSM MAB and as-cast LSM MAB after cavitation in 3.5% NACL solution for 5 H. The total weight loss t of as-cast and LSM MAB is larger than the total weight loss t of pure e and pure C, that is, there is a positive interaction between cavitation and corrosion, which promotes the material surface damage together. The percentage of pure cavitation damage in the total weight loss of Lsm Mab and LSM MAB was 71.1% and 50.8% respectively, the results show that the mechanical impact during cavitation is the dominant factor for cavitation damage of as-cast and Lsm Mab. In the weightlessness due to the interaction between the cast and Lsm Mab, ? The ratio of e to e shall be greater than? C, that is, corrosion to promote the proportion of cavitation larger. This is because corrosion can coarsen the surface of materials, worsen mechanical properties, and accelerate cavitation erosion.

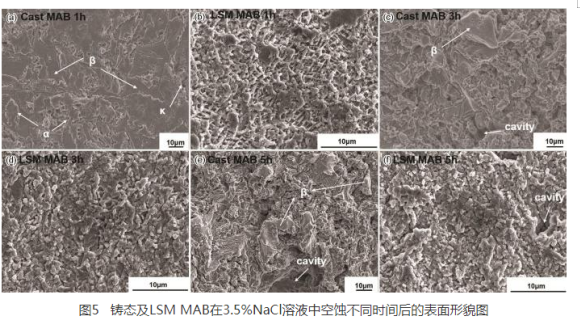

2.4 the surface morphology of as-cast and LSM MAB after cavitation in 3.5% NACL solution for different time is shown in Fig. 5. Crack appeared at α/β phase boundary of as cast MAB and around κ phase after 1 h cavitation, which was due to different composition structure of each phase and different response to cavitation stress, cavitation pits are formed, as shown in Fig. 5A. In addition, smaller size cavitation pits have been found in the softer α phase, and the higher hardness β phase has less damage. After 3 hours of Cavitation, the α phase of the cast MAB was severely deformed, the original structure could not be identified, the β phase was cleavage fractured, the Surface roughness increased obviously, and the cavitation pits were honeycomb-shaped, as shown in Fig. 5C. After 5 hours of Cavitation, the size of cavitation pit increases and the extent of cavitation damage increases, as shown in Fig. 5E. Because the microstructure of β phase in Lsm Mab is single and the hardness is obviously higher than that of as-cast Mab, under cavitation stress, there is no drop of big particle phase and cleavage fracture of big β phase in as-cast microstructure, and the extent of cavitation damage is light and uniform, as shown in Fig. 5B, D and F, smaller cavitation pits appear on the surface after 5 H cavitation (Fig. 5F) . From the view of cavitation morphology, LSM MAB showed excellent cavitation resistance.

3. Conclusion

(1) The remelted zone microstructure of MAB treated by LSM is fine and single β phase microstructure. Compared with as-cast Mab, the hardness of the Matrix was increased by about 45% after LSM treatment.

(2) at the same cavitation time, the cavitation damage of LSM MAB is smaller. The weight loss rate of Lsm Mab is only 3/5 of that of as-cast Mab after 5 H cavitation in 3.5% NACL solution, which means that LSM treatment improves the cavitation resistance of as-cast Mab by 1.64 times.

(3) in 3.5% NACL solution, the CATHODIC and anodic processes of as-cast and Lsm Mab are similar, but the potential of as-cast Mab is lower and the corrosion tendency is higher. Under static and cavitation conditions, the current density of as-cast and Lsm Mab is close, because the CATHODIC process under static and cavitation conditions is oxygen reduction reaction. The diffusion of oxygen is accelerated under cavitation condition, so the corrosion current density is higher than that under static condition.

(4) in 3.5% NACL solution, the interaction of corrosion and cavitation erosion makes the material damage more serious. For as-cast and Lsm Mab, mechanical damage is the dominant factor of cavitation damage. In the case of interaction-induced weightlessness, ? E as a percentage of total cavitation loss is greater than? C, I. E. Corrosion Promoting cavitation damage caused by more significant. (5) the results of cavitation damage morphology showed that kappa phase and β phase cleavage fracture appeared in the as-cast Mab under cavitation stress, and the surface damage of Lsm Mab was lighter and distributed more evenly than that of as-cast Mab. The surface hardness of as-cast Mab is improved by LSM treatment, and the microstructure is refined obviously, so the cavitation corrosion resistance is improved remarkably.

Source: Chinese Journal of Corrosion and protection, author: Song Qi Ning, Wu Zhu Yu, Li Huilin, Tong Yao, Xu Nan, Bao Ye Feng

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.