Release time:2021-03-19Click:995

ABSTRACT: The causes of cracking of aluminum brass tubes for condenser were analyzed by means of macroscopic examination, chemical composition analysis, metallographic examination, residual stress test and electron microscopic observation. The results showed that the residual acid solution was partly left in the process of acid pickling due to insufficient de-stress annealing and incomplete rinsing in the later stage of acid pickling, stress Corrosion cracking of aluminum brass tubes for condensers.

Keywords: metallographic structure; residual stress; stress corrosion cracking; Middle Diagram of Aluminum Brass Tube; classification number: TG111.91; TG146.1 + 1 Document identification number: A article number: 1001-3814(2020)16-0159-03 by Wu Chaoqun

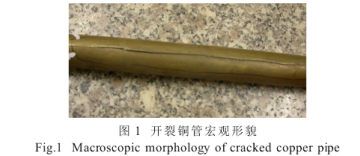

After the installation of condenser al-brass tubes in a power station, the water test was carried out. The leakage occurred during the test and many al-brass tubes were found to be cracked. The cracks are distributed along the axial direction. The maximum length of the cracks is about 150mm. The surface of the al-brass tube is yellowish-brown and the crack is gray-white.

The cracked copper tubes are manufactured according to GB/T8890-2007"seamless copper alloy tubes for heat exchangers" . The material used is HAl77-2 aluminum brass, and the specification model is quasi-4mm 0.8 mm soft state. After annealing, pickling, extruding and drawing, the straight pipes are made to the specified specifications.

1 physical and chemical examination

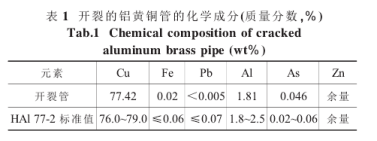

1.1 chemical composition analysis of materials the results of chemical composition analysis of cracked aluminum brass tubes are shown in Table 1.

1.2 metallographic structure

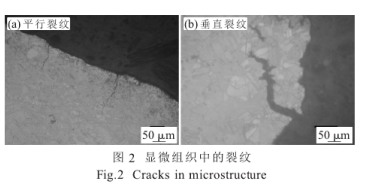

Metallographic examination is carried out by taking samples perpendicular to and parallel to the crack direction near the crack. The results show that the microstructure of Al Brass tube is single phase (Cu) and a few twin crystals appear. The average grain size of Al brass tube is between 0.020 mm and 0.026 mm according to YS/T347-2004《 method for measuring average grain size of copper and copper alloy 》 , there are a large number of cracks, mainly intergranular cracks, a small number of transgranular cracks, the microstructure of the cracks as shown in figure 2

1.3 mechanical properties

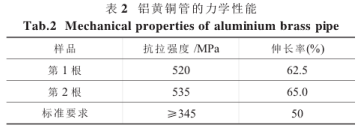

Two copper tubes were randomly selected from the cracked aluminum brass tubes for mechanical testing. The results are shown in Table 2.

1.4 residual stress test

Taking samples from these cracked aluminum brass tubes, according to GB/T10567.2-2007"method of ammonia fumigation test for residual stress of copper and copper alloy processing materials" , the residual stress test of the aluminum brass tubes was carried out and observed after 24 hours of ammonia fumigation, two of the six copper tubes were found to be cracked, the length of the crack was about 40mm, one was slightly cracked and the other three were in good condition. The macro-morphology of the cracked al-brass tube after test is shown in Fig. 3.

1.5 Electron probe observation

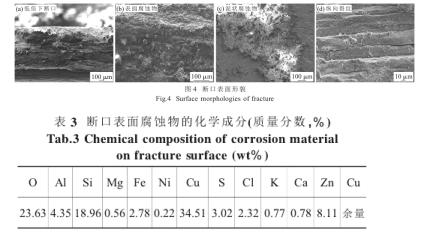

The surface of the aluminum brass tube is brown yellow when observed by naked eye, and the surface of the inner wall is dark yellow without obvious plastic deformation. Observing the fracture surface with JXA-8100 electron probe, it can be seen that there is a large amount of corrosion on the fracture surface, which is loose or muddy (Fig. 4(a) ~ (c)) . After cleaning, it can be seen that the fracture surface is concave and jagged, there are a large number of longitudinal cracks (Fig. 4(D)) . The corrosion on the fracture surface was analyzed by EDS. The results are shown in table 3. It can be seen from table 3 that the corrosion products contain obvious corrosive elements such as S, CL and impurity elements such as SI, Fe, K and CA.

2. Analysis and discussion

According to the above analysis results and the GB/T8890-2007 standard, the chemical composition of the cracked aluminum brass tube for condenser can meet the requirements of HAl77-2 aluminum brass standard, the mechanical properties and grain size of Al Brass tube are in accordance with the standard, but some AL brass tubes are not up to the standard when the residual stress is detected. The microstructure of the copper tube shows that there is no obvious deformation of the grains near the crack, the size of the crack is slightly different, the crack extends along the grain boundary, part of the crack is separated inwards, and it has obvious stress corrosion cracking characteristics. The surface electron microscope observation shows that there is no obvious plastic deformation at the crack of the copper tube, and there is a thick layer of corrosion material on the surface of the fracture surface and nearby, which contains a lot of corrosive elements such as s and CL,

After removing the surface adhesion, a large number of secondary cracks and transgranular cracks are found on the fracture surface. The results of residual stress test show that there is obvious residual stress in the aluminum brass tubes of the condenser. In the process of cold drawing and stamping, the brass tube can produce large lattice distortion. If there is no de-stress annealing or no de-stress annealing, there will be residual stress, self-opening in corrosive medium [1-2]. The residual stress of aluminum brass tubes is formed in the process of rolling, cold drawing and so on, and can be removed by the later heat treatment process, but the stress in these tubes can not be completely eliminated due to insufficient de-stress annealing during the heat treatment process, in addition, the surface of the copper tube is affected by the corrosion materials rich in s and Cl, and the corrosion spreads along the grain with uneven stress distribution, the stress corrosion cracking (SCC) of aluminum brass tubes for condensers was caused by the interaction of the above two factors.

3. Conclusion

There are two main reasons for the stress corrosion cracking of aluminum brass tubes used in condensers:

(1) when the aluminum brass tubes are heat treated, the stress relief annealing is not sufficient.

(2) in the later stage of pickling, a small amount of pickling solution remained on the surface of the aluminum brass tube because of incomplete cleaning.

Source: Chinanews.com by Wu Chaoqun

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.